In the metal industry, cutting and changing the shape of sheets are among the main activities. These works are done by means of tools that have advantages and disadvantages depending on their type. One of the important tools in cutting and changing the shape of the sheet is laser cutting. In the following, we will examine the laser sheet cutting method and the advantages and features of laser sheet cutting.

laser cut

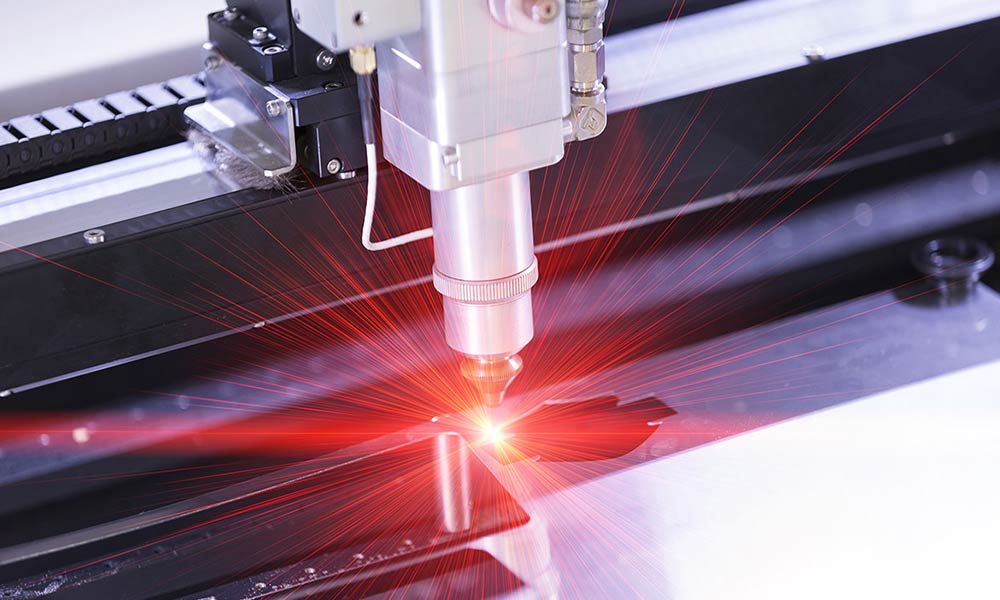

In laser cutting, a laser beam passes over the metal piece and makes the cut. The laser beam has the ability to cut and change the shape of sheets with high thickness and large dimensions. For cutting and changing the shape of parts with high accuracy and small dimensions, laser cutting is also suitable. By using a laser, complex molds are cut with high accuracy and due to the lack of direct contact of the tool with the metal, the surface of the part does not suffer any kind of scratch. Also, against pressure and impact, the parts made with this method are more resistant and do not need to pay more for post-processing, coating or painting.

However, the laser cutting method is more expensive than other methods such as punching, and it also consumes more energy due to the need for more advanced equipment. Also, laser cutting may be difficult to cut and shape very thick sheets.

Features of laser cutting

As we said, laser cutting is one of the advanced methods for cutting sheets that uses laser technology to perform cutting operations. Laser sheet cutting has unique features that distinguish it from other methods. One of the prominent features of sheet laser cutting is its high accuracy. Using a laser, parts can be cut very accurately and fine details can be preserved with high quality. This feature is especially valuable in industries that require precision parts.

Another feature that distinguishes laser cutting is its cutting speed. Laser technology cuts parts quickly and effectively, increasing productivity and reducing production time. The multifunctional cutting capability of sheet laser cutting makes it possible to cut various materials such as metals, plastics, wood and even stones. This feature increases flexibility in the use of laser sheet cutting and allows users to use a suitable cutting method for different materials. Also, during the laser cutting of the sheet, a limited projective temperature is transferred to the part, which reduces the deformation and differentiates the unwanted marginal parts. This feature maintains the accuracy and quality of the cut piece.

Finally, another characteristic of sheet laser cutting is the lack of contact between the laser and the material. In this method, the laser acts indirectly on the part and may not have direct access to the sensitive parts of the part. This feature reduces the risk of damage to the part and improves safety in the cutting process.

Advantages of sheet laser cutting

Sheet cutting using laser technology has many advantages, which can be mentioned as follows:

Creativity in designing and creating complex designs

Very high precision in cutting parts

High cutting speed

Low price compared to other methods

Maintain the same precision in repeated cuts

High quality cut edges

Reducing waste and discarding parts

No change in the structure of metals after cutting

The possibility of cutting in series

Simultaneous production of parts with the same thickness

Elimination of multiple steps in the production process of parts

In the laser cutting method, there is no need to move the sheet to determine its position. Not moving the sheet prevents scratches on the bottom surface of the sheet. Also, due to no need to move the sheet, high-quality cutting is achieved. This method uses automatic loading, transfer and loading of raw sheets; Therefore, there is no need for human power or mechanical arm to perform the cutting operation. This increases the production capacity and reduces the work time.

In the metal industry, cutting and changing the shape of sheets are among the main activities. These works are done by means of tools that have advantages and disadvantages depending on their type. One of the important tools in cutting and changing the shape of the sheet is laser cutting. In the following, we will examine the laser sheet cutting method and the advantages and features of laser sheet cutting.

laser cut

In laser cutting, a laser beam passes over the metal piece and makes the cut. The laser beam has the ability to cut and change the shape of sheets with high thickness and large dimensions. For cutting and changing the shape of parts with high accuracy and small dimensions, laser cutting is also suitable. By using a laser, complex molds are cut with high accuracy and due to the lack of direct contact of the tool with the metal, the surface of the part does not suffer any kind of scratch. Also, against pressure and impact, the parts made with this method are more resistant and do not need to pay more for post-processing, coating or painting.

However, the laser cutting method is more expensive than other methods such as punching, and it also consumes more energy due to the need for more advanced equipment. Also, laser cutting may be difficult to cut and shape very thick sheets.

Features of laser cutting

As we said, laser cutting is one of the advanced methods for cutting sheets that uses laser technology to perform cutting operations. Laser sheet cutting has unique features that distinguish it from other methods. One of the prominent features of sheet laser cutting is its high accuracy. Using a laser, parts can be cut very accurately and fine details can be preserved with high quality. This feature is especially valuable in industries that require precision parts.

Another feature that distinguishes laser cutting is its cutting speed. Laser technology cuts parts quickly and effectively, increasing productivity and reducing production time. The multifunctional cutting capability of sheet laser cutting makes it possible to cut various materials such as metals, plastics, wood and even stones. This feature increases flexibility in the use of laser sheet cutting and allows users to use a suitable cutting method for different materials. Also, during the laser cutting of the sheet, a limited projective temperature is transferred to the part, which reduces the deformation and differentiates the unwanted marginal parts. This feature maintains the accuracy and quality of the cut piece.

Finally, another characteristic of sheet laser cutting is the lack of contact between the laser and the material. In this method, the laser acts indirectly on the part and may not have direct access to the sensitive parts of the part. This feature reduces the risk of damage to the part and improves safety in the cutting process.

Advantages of sheet laser cutting

Sheet cutting using laser technology has many advantages, which can be mentioned as follows:

Creativity in designing and creating complex designs

Very high precision in cutting parts

High cutting speed

Low price compared to other methods

Maintain the same precision in repeated cuts

High quality cut edges

Reducing waste and discarding parts

No change in the structure of metals after cutting

The possibility of cutting in series

Simultaneous production of parts with the same thickness

Elimination of multiple steps in the production process of parts

In the laser cutting method, there is no need to move the sheet to determine its position. Not moving the sheet prevents scratches on the bottom surface of the sheet. Also, due to no need to move the sheet, high-quality cutting is achieved. This method uses automatic loading, transfer and loading of raw sheets; Therefore, there is no need for human power or mechanical arm to perform the cutting operation. This increases the production capacity and reduces the work time.