Flashing refers to thin, impermeable constructs that are used to prevent the infiltration and leakage of water into buildings, and to direct water away from joints and intersections between walls and roofs. Flashings play a crucial role in connecting different roof materials and members, especially in areas such as skylights, chimneys, facility valves, and air vents, where they are extensively used. They serve as longitudinal members to prevent water penetration and ensure waterproofing in these critical areas.

What are the categories of flashings?

There are two main types of flashings:

- A) Exposed (external) Flashings: Exposed flashings are partially visible from the outside and are typically made of sheet metal.

- B) Embedded (internal) Flashings: Embedded (or concealed) flashings can be metallic or non-metallic and are commonly used at the base of cavity walls, above openings, and at sills and shelf corners. These flashings support and transmit the dead load of bricks to the building frame and under-coverings. They are usually hidden from view to maintain a seamless appearance.

Types of Flashings:

Flashing is a crucial component of a building’s waterproofing system. There are various types of flashing, each with its specific purpose and location.

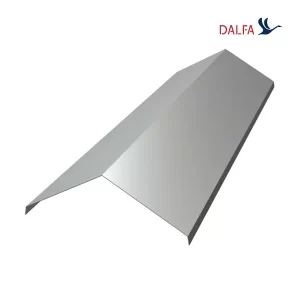

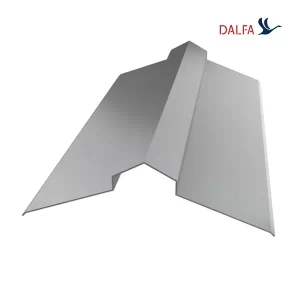

- Roof Flashing: This type of flashing is installed around ridges or intersections on a roof to direct water away from joints.

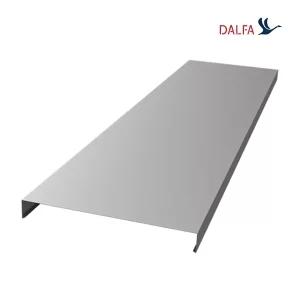

- Wall Flashing: Wall flashing is usually installed at wall breaks, such as windows, to prevent water from entering or to direct water that has entered outside.

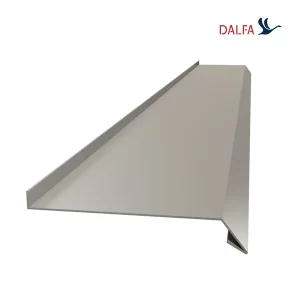

- Threshold Flashing: Threshold flashing is hidden under windows or door thresholds to prevent water from entering.

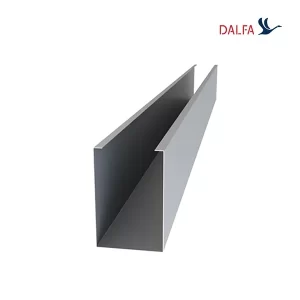

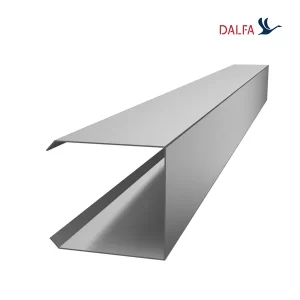

- Channel Flashing: This is a U-shaped channel used where the edge of a tile roof meets a wall.

- Through-the-Wall Flashing: This type of flashing directs water to the weep holes by covering the thickness of the wall.

- Cap Flashing: Cap flashing is placed above windows and doors.

- Drip Edge: A metal protrusion often found on the edges of a roof.

- Step Flashing: Step flashing is used in joints on a slope, such as around chimney stacks on sloped roofs. It consists of overlapping flush materials.

- Kickout Flashing: This is the lowest flash step at the end of the ceiling/wall junction, used to divert water away from the wall.

- Pipe Flashing: This type of flashing is used in places where roofs are penetrated by pipes.

- Valley Flashing: Where two intersecting roof panels form a valley, this type of flashing is used to prevent water from collecting in that area.

How is flashing installed?

Flashing is a crucial element in roofing and construction, especially at the junctions where a pitched roof meets a vertical sidewall to form a horizontal line. It allows the roof to be installed closer to the brickwork, such as where a lower pitched roof meets a wall, a roof meets a chimney, or a garden roof meets a house wall. Step flashing, consisting of a series of individual pieces, provides better protection against leaks than continuous flashing. Even if one piece fails, the water will hit the next lower piece, directing it over the shingle and off the roof.

Flashing materials

Various materials can be used for flashings, but it is essential that they are not damaged by contact with incompatible materials and are impermeable to water. The most commonly used flashing materials are metal, plastic, and rubber.

Metal flashing

Lead is the traditional flashing material used for its durability around roof supports like chimneys. The minimum specification for lead flashing is Code 4 (1.8 mm), which is both malleable and resistant to fatigue cracks due to expansion and contraction. Code 3 (1.32 mm) is thinner, lighter, and less expensive, and is often used for lead soakers, which are hidden waterproofing sections placed under plain boards and tiles.

Aluminum is another metal flashing material that is durable and relatively inexpensive, but it corrodes when in contact with wood under pressure, as well as wet mortar and plaster.

Copper is malleable, strong, and highly resistant to the corrosive effects of mortars and wood preservatives. Cold-rolled copper is preferred over soft copper because it offers greater resistance to expansion and contraction stresses. However, soft copper is useful where there are complex roof shapes.

In summary, flashing plays a critical role in maintaining the integrity of roofs and structures. For further information on flashing and its types, you can contact experts like Dalfa company.